-

Understanding the High-Pitched Noise in Ultrasonic Cleaners: Causes and Implications

Understanding the High-Pitched Noise in Ultrasonic Cleaners: Causes and Implications

Ultrasonic cleaners are invaluable tools in both industrial and consumer applications, renowned for their ability to clean intricate objects efficiently through high-frequency sound waves. However, users often report hearing a distinctive high-pitched noi

-

How Ultrasonic Cleaning Machines Meet the High Standards for Aerospace Components

How Ultrasonic Cleaning Machines Meet the High Standards for Aerospace Components

-

Meeting High Standards of Cleanliness for Electronic Products with Ultrasonic Cleaning Machines

Meeting High Standards of Cleanliness for Electronic Products with Ultrasonic Cleaning Machines

Introduction In the electronics industry, the cleanliness of components and assemblies is paramount. Contaminants such as dust, oils, fingerprints, and residues can significantly affect the performance, reliability, and lifespan of electronic devices.

-

Energy Efficiency in Ultrasonic Cleaners: Harnessing High-Performance Cleaning with Low Energy Consumption

Energy Efficiency in Ultrasonic Cleaners: Harnessing High-Performance Cleaning with Low Energy Consumption

Introduction Ultrasonic cleaning technology has revolutionized the cleaning industry by offering efficient solutions for a wide range of applications. As concerns about energy consumption and environmental sustainability grow, ultrasonic cleaners stand

-

Exploring the Advantages of Ultrasonic Cleaning Equipment: A High-Efficiency Cleaning Solution

Exploring the Advantages of Ultrasonic Cleaning Equipment: A High-Efficiency Cleaning Solution

Ultrasonic cleaning equipment has emerged as a leading solution in the field of high-efficiency cleaning, offering unparalleled advantages over traditional methods. This technology leverages the power of ultrasonic waves to remove contaminants from surfac

-

Exploring High-Power Ultrasonic Cleaning Machines: Benefits and Considerations

Exploring High-Power Ultrasonic Cleaning Machines: Benefits and Considerations

Ultrasonic cleaning machines are vital equipment used across various industries for efficient and thorough cleaning of parts and components. One crucial aspect of these machines is their power rating, measured in watts (W), which determines their cleaning

-

Ultrasonic Cleaning Machines: A High-Efficiency Solution for Electronic Component Cleaning Challenges

Ultrasonic Cleaning Machines: A High-Efficiency Solution for Electronic Component Cleaning Challenges

In the realm of modern technology, electronic components serve as the backbone of various industries. However, within the electronic manufacturing process, the task of cleaning electronic components has long posed challenges. With ongoing technological ad

-

Precision Cleaning Revolution: Unveiling the High Performance of Ultrasonic Cleaning Machines

Precision Cleaning Revolution: Unveiling the High Performance of Ultrasonic Cleaning Machines

In the realm of precision manufacturing, the meticulous cleaning of components stands as a pivotal step in ensuring product performance and reliability. Ultrasonic cleaning machines, as an advanced cleaning technology, offer a new perspective in precision

-

Ultrasonic Cleaning Machine: Pioneering High-Efficiency Applications in Energy Equipment Manufacturing

Ultrasonic Cleaning Machine: Pioneering High-Efficiency Applications in Energy Equipment Manufacturing

As the manufacturing processes for energy equipment become more sophisticated, the demand for advanced cleaning technologies has risen significantly. Among these, the ultrasonic cleaning machine stands out as a highly efficient tool, showcasing remarkable

-

Ultrasonic Cleaning Machines: A High-Tech Odyssey in Cleaning Efficiency

Ultrasonic Cleaning Machines: A High-Tech Odyssey in Cleaning Efficiency

In the era of rapid technological advancement, ultrasonic cleaning machines have emerged as a technological marvel in the realm of cleanliness. Leveraging a unique working principle and delivering exceptional cleaning efficacy, these high-tech devices hav

-

Ultrasonic Cleaning Machines: Pioneering Industry-Leading Technology for High-Standard Cleaning

Ultrasonic Cleaning Machines: Pioneering Industry-Leading Technology for High-Standard Cleaning

In the realm of manufacturing and production, achieving high standards of cleanliness is a critical factor in ensuring product quality. Ultrasonic cleaning technology stands out as an industry-leading and highly efficient method that excels not only in re

-

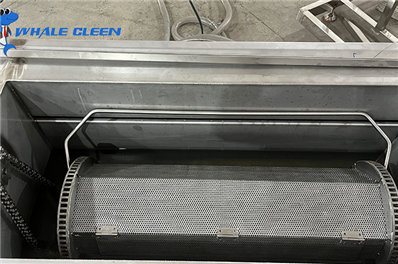

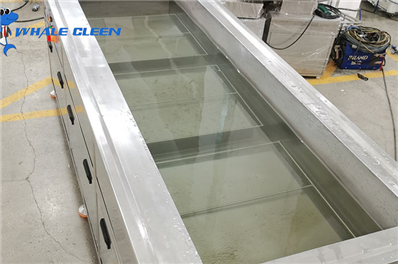

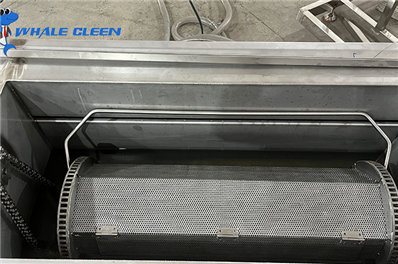

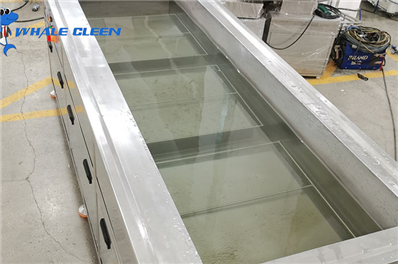

How to judge whether the vibrating plate of the ultrasonic cleaning machine is high quality?

How to judge whether the vibrating plate of the ultrasonic cleaning machine is high quality?

The more expensive the ultrasonic cleaning machine, the better the cleaning effect, the cheaper the price, the worse the machine's cleaning effect. It depends on the configuration of the machine. The better the material configuration, the more cost-ef

Understanding the High-Pitched Noise in Ultrasonic Cleaners: Causes and Implications

Understanding the High-Pitched Noise in Ultrasonic Cleaners: Causes and Implications

How Ultrasonic Cleaning Machines Meet the High Standards for Aerospace Components

How Ultrasonic Cleaning Machines Meet the High Standards for Aerospace Components

Meeting High Standards of Cleanliness for Electronic Products with Ultrasonic Cleaning Machines

Meeting High Standards of Cleanliness for Electronic Products with Ultrasonic Cleaning Machines

Energy Efficiency in Ultrasonic Cleaners: Harnessing High-Performance Cleaning with Low Energy Consumption

Energy Efficiency in Ultrasonic Cleaners: Harnessing High-Performance Cleaning with Low Energy Consumption

Exploring the Advantages of Ultrasonic Cleaning Equipment: A High-Efficiency Cleaning Solution

Exploring the Advantages of Ultrasonic Cleaning Equipment: A High-Efficiency Cleaning Solution

Exploring High-Power Ultrasonic Cleaning Machines: Benefits and Considerations

Exploring High-Power Ultrasonic Cleaning Machines: Benefits and Considerations

Ultrasonic Cleaning Machines: A High-Efficiency Solution for Electronic Component Cleaning Challenges

Ultrasonic Cleaning Machines: A High-Efficiency Solution for Electronic Component Cleaning Challenges

Precision Cleaning Revolution: Unveiling the High Performance of Ultrasonic Cleaning Machines

Precision Cleaning Revolution: Unveiling the High Performance of Ultrasonic Cleaning Machines

Ultrasonic Cleaning Machine: Pioneering High-Efficiency Applications in Energy Equipment Manufacturing

Ultrasonic Cleaning Machine: Pioneering High-Efficiency Applications in Energy Equipment Manufacturing

Ultrasonic Cleaning Machines: A High-Tech Odyssey in Cleaning Efficiency

Ultrasonic Cleaning Machines: A High-Tech Odyssey in Cleaning Efficiency

Ultrasonic Cleaning Machines: Pioneering Industry-Leading Technology for High-Standard Cleaning

Ultrasonic Cleaning Machines: Pioneering Industry-Leading Technology for High-Standard Cleaning

How to judge whether the vibrating plate of the ultrasonic cleaning machine is high quality?

How to judge whether the vibrating plate of the ultrasonic cleaning machine is high quality?